Find out more about sustainability in steel fabrication. Whether you're a builder, architect, or environmentally-conscious consumer, delve into our insights to understand how sustainability in steel fabrication is shaping a greener, more responsible future.

Recycled Steel: Reducing Environmental Impact through Sustainable Sourcing

In steel fabrication, the pursuit of sustainability has emerged as a paramount concern, driving innovation towards more environmentally responsible practices. Central to this transformation is the incorporation of recycled steel, a game-changing approach that not only addresses resource depletion but also reduces the carbon footprint associated with traditional steel production.

Recycled steel, obtained from discarded steel products or manufacturing scrap, offers a significant reduction in energy consumption and greenhouse gas emissions compared to virgin steel production.

The process involves melting down existing steel, thereby saving up to 60% of the energy required to create steel from raw materials. This reduction in energy consumption leads to fewer emissions of carbon dioxide and other pollutants, mitigating the industry's contribution to climate change.

Furthermore, the utilisation of recycled steel diverts tons of steel waste from landfills, curbing environmental degradation. This shift aligns with the principles of a circular economy, where materials are continually reused and recycled, minimising the demand for virgin resources. By embracing recycled steel, manufacturers not only diminish the strain on natural resources but also decrease water usage, air pollution, and the ecological footprint of their operations.

The integration of recycled steel within the realm of steel fabrication heralds a crucial stride towards sustainability. By opting for this environmentally responsible alternative, stakeholders in the industry can actively contribute to reducing environmental impact, conserving resources, and paving the way for a more ecologically balanced future.

Energy-Efficient Manufacturing: Implementing Green Practices in Steel Fabrication

In the dynamic arena of steel fabrication, a growing emphasis on sustainability has sparked a noteworthy shift towards energy-efficient manufacturing practices. This pivotal approach not only aligns with environmental stewardship but also yields economic benefits.

By adopting green techniques such as advanced process control, optimised equipment, and renewable energy sources, steel fabrication can substantially curtail energy consumption and associated carbon emissions.

Implementing energy-efficient measures not only minimises operational costs but also mitigates the industry's ecological footprint. Embracing technologies like electric arc furnaces and energy recovery systems significantly reduces energy use while maintaining high production standards. Moreover, integrating renewable energy sources like solar and wind power into the manufacturing process further bolsters the sector's sustainability profile.

By prioritising energy efficiency, steel fabrication can usher in a new era of responsible production. This approach not only underscores the industry's commitment to environmental preservation but also sets an inspiring precedent for other sectors. Ultimately, the fusion of green practices and steel fabrication holds the promise of a harmonious coexistence between industrial progress and ecological well-being.

Waste Reduction and Resource Optimisation: Minimising Material Wastage

In the realm of steel fabrication, the pursuit of sustainability has given rise to innovative strategies centred around waste reduction and resource optimisation. Addressing the challenge of material wastage is not only environmentally prudent but also financially savvy. By minimising scrap, enhancing production efficiency, and maximising the utility of raw materials, the steel fabrication industry can make significant strides towards a more sustainable future.

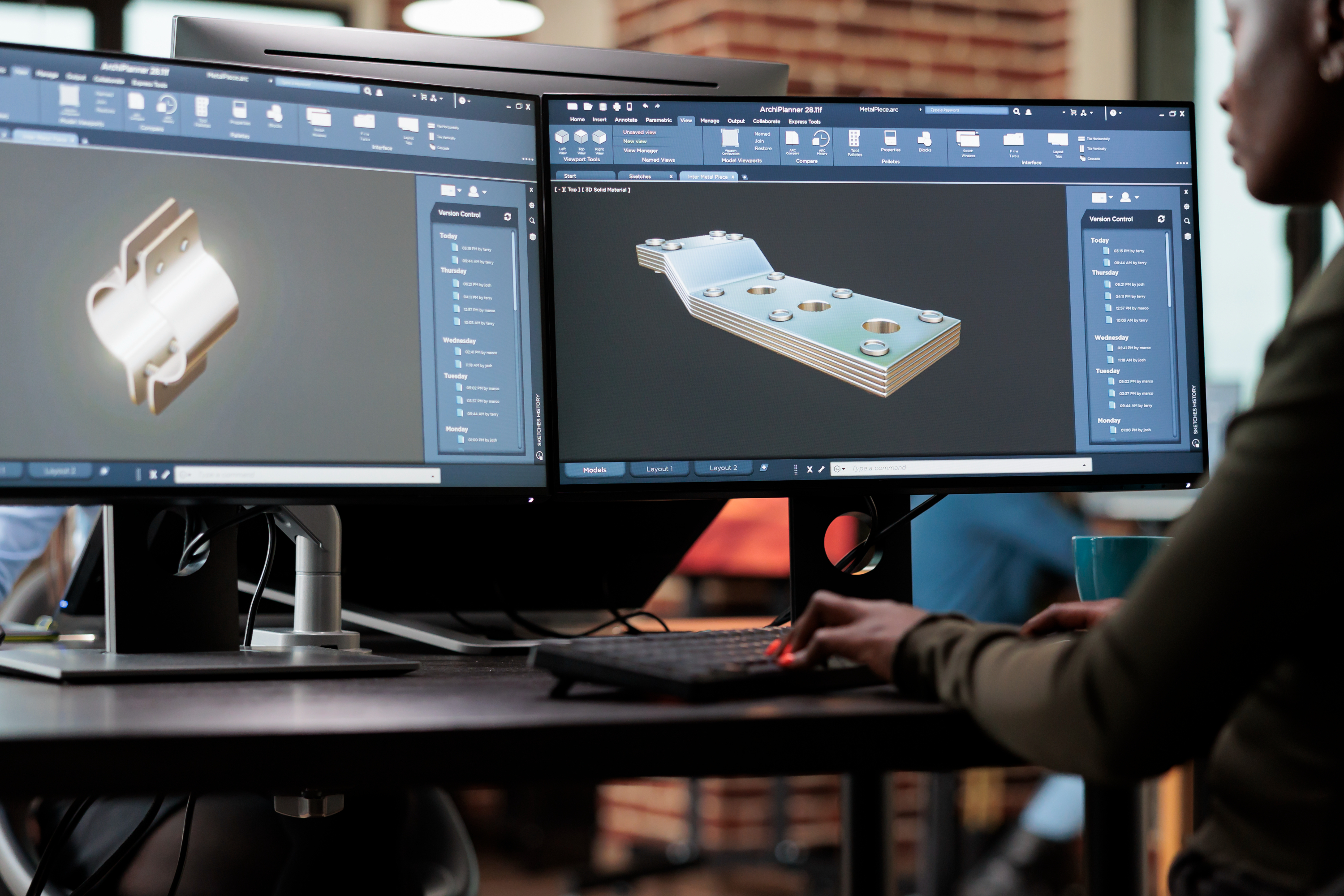

One key approach involves adopting cutting-edge technologies such as computer-aided design (CAD) and simulation software, enabling precise measurements and minimising errors.

This, in turn, reduces the need for rework and excessive material usage. Additionally, the implementation of lean manufacturing principles streamlines processes, eliminating unnecessary steps and minimising the creation of surplus materials.

Furthermore, embracing a circular economy mindset underscores the importance of reusing and recycling materials wherever possible. Reclaimed steel not only curtails the demand for virgin resources but also lessens the burden on landfills.

Collaboration within the supply chain also plays a pivotal role in waste reduction. Close communication with suppliers ensures that materials are ordered in precise quantities, preventing overstocking and subsequent waste. Furthermore, partnerships can foster innovative solutions for repurposing by-products, turning potential waste into valuable resources.

Longevity and Reusability: The Sustainable Lifecycle of Steel Structures

The realm of steel fabrication is experiencing a profound shift towards sustainability, with a spotlight on the longevity and reusability of steel structures. This focus transcends the conventional notion of construction as a one-time endeavour, instead emphasising the enduring value of steel in a circular economy.

Steel structures possess inherent durability, capable of withstanding harsh conditions and the test of time. This longevity minimises the need for frequent replacements, reducing the overall environmental impact associated with construction.

Additionally, the adaptability of steel allows for easy modifications and repurposing, extending the lifecycle of structures and diverting materials from landfills.

The principle of reusability is central to sustainable steel fabrication. Steel components can be disassembled, refurbished, and integrated into new projects, significantly reducing demand for fresh resources. This not only conserves energy but also reduces carbon emissions linked to manufacturing new materials.

By prioritising the longevity and reusability of steel structures, the industry embraces a holistic approach that encompasses efficient design, responsible construction, and extended service life. This shift aligns with the ethos of sustainability, where steel's enduring qualities harmonise with environmental well-being and economic prudence.

Green Certifications and Standards: Ensuring Sustainability Compliance in Steel Fabrication

Prominent certifications like BREEAM (Building Research Establishment Environmental Assessment Method) and LEED (Leadership in Energy and Environmental Design) validate the sustainability of steel fabrication projects. By adhering to stringent criteria related to energy efficiency, waste reduction, and material sourcing, these certifications incentivise the adoption of green practices.

ISO 14001, another vital standard, focuses on environmental management systems, facilitating the integration of sustainable strategies into daily operations. These certifications not only reflect a commitment to reducing carbon footprints but also enhance a company's reputation, fostering client trust and investor confidence.

Furthermore, the UK government's Construction Strategy and Clean Growth Strategy emphasise sustainable construction practices, urging steel fabricators to meet specific environmental targets. Compliance with these directives not only contributes to a greener industry but also positions businesses favourably within a competitive market increasingly attuned to sustainability.

In conclusion, green certifications and standards are integral to advancing sustainability in UK steel fabrication. By championing eco-conscious practices, the industry not only meets regulatory demands but also embraces a pivotal role in crafting a more resilient, environmentally harmonious built environment.